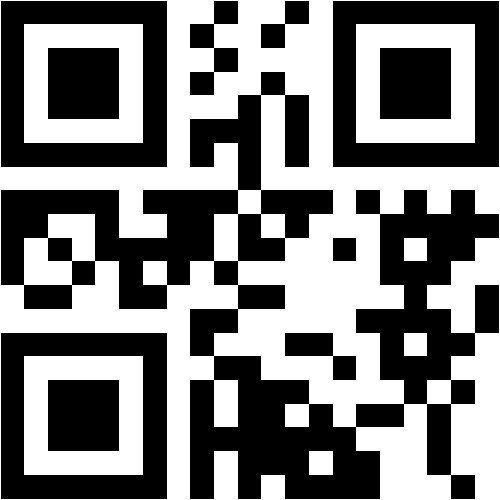

Ahmad Maksum

@mesin.pnj.ac.id/readmore

Research Center for eco-friendly Technology, Department of Mechanical Engineering

Politeknik Negeri Jakarta

Scopus Publications

Scopus Publications

Eni Febriana, Wahyu Mayangsari, Sigit Dwi Yudanto, Eko Sulistiyono, Murni Handayani, Florentinus Firdiyono, Ahmad Maksum, Agus Budi Prasetyo, and J.W. Soedarsono

Elsevier BV

Agus Paul Setiawan Kaban, Johny Wahyuadi Soedarsono, Mochammad Syaiful Anwar, Wahyu Mayangsari, Ahmad Maksum, Aga Ridhova, Rini Riastuti, Dedy Iskandar, and Ayende

Elsevier BV

A. Zuhri, A. E. Pramono, I. Setyadi, A. Maksum, and N. Indayaningsih

Universidad Nacional Autonoma de Mexico

This experimental research aimed to develop a conductive polymer composite (CPC) material for electromechanical devices. The composite was made by incorporating conductive micro carbon derived from rice husks into a Linear Low-Density Polyethylene (LLDPE) polymer matrix using hot compaction. Variations of filler composition were used, with carbon loading of 50%, 45%, and 40%, and mesh sizes of #150, #200, and #250. The experimental results showed that particle size variations did not significantly affect composite density, but higher mesh selection improved filler dispersion within the matrix, resulting in higher electrical conductivity values. The optimal conductivity value of 9.43E-04 S/cm was achieved with a micro-carbon composition of 50% loading. However, decreasing micro carbon loading had a more significant impact on reducing electrical conductivity values.

Nurhayati Indah Ciptasari, Murni Handayani, Afif Akmal Afkauni, Caesart Leonardo Kaharudin, Adhi Dwi Hatmanto, Ahmad Maksum, Rini Riastuti, and Johny W. Soedarsono

AIP Publishing

Wahyu Mayangsari, Agus Budi Prasetyo, Eni Febriana, Ahmad Maksum, Rudi Subagja, F Firdiyono, and Johny Wahyuadi Soedarsono

SciCell

Ferronickel slag is a by-product that was obtained from ferronickel production and contains Si and Mg as the main elements. Decomposition process using alkali could decrease energy consumption to process ferronickel slag by decreasing its melting point. The mixing methods prior to the decomposition process could significantly affect interaction between reactants over the process, therefore it is essential to study. The aim of this study is to determine the effect of mixing methods of ferronickel slag and NaOH prior decomposition process on the chemical composition, phase, and microstructure of decomposed ferronickel slag. Two different mixing methods, physical mixing, and impregnation, followed by roasting process at 350 ℃ for 60 minutes were performed, characterized, and analyzed. Thermodynamic analysis was calculated and shows having a good agreement with the characterization results which formation of sodium silicate, magnesium hydroxide and iron oxide were identified. Distribution of product layer of RI can be determined, while spotty decomposition was clearly identified. The effectiveness of impregnation over physical mixing was investigated.

Reza M. Ulum, Natalin, Rini Riastuti, Wahyu Mayangsari, Agus B. Prasetyo, Johny W. Soedarsono, and Ahmad Maksum

MDPI AG

Ferronickel slag is a by-product of nickel smelting that provides an abundant silica source. Based on data, every ton of nickel production is equal to eight tons of ferronickel slag production, increasing without any recycling process. It is essential to create an end-to-end process for nickel production and its by-products because this would be a problem in the future and is relevant for many industrialized countries. This study describes a strategy to process ferronickel slag to produce silica. A pyrometallurgy–hydrometallurgy process and ferronickel slag were used to increase the silica content. The process was conducted through alkali fusion; the ferronickel slag was mixed with sodium carbonate at a temperature of 1000 °C for an hour and continued via leaching, precipitation, and cleaning processes. The leaching process was conducted with four concentrations (4 M, 6 M, 8 M, and 10 M) of sodium hydroxide and three different leaching durations (2 h, 4 h, and 6 h). Using hydrochloric acid (HCl) at pH 2 and deionized (DI) water cleaning, the precipitation process was adopted to synthesize a silica powder with the lowest agglomeration and enhance its purity. Characterization was carried out using X-ray Diffraction (XRD), Scanning Electron Microscopy–Energy-Dispersive Emission (SEM-EDS), X-ray Fluorescence (XRF), and Inductively Coupled Plasma–Optical Emission Spectroscopy (ICP-OES). This study highlighted silica characteristics that indicate high recovery by 85% through alkali fusion, HCl leaching, precipitation, and deionized water cleaning.

Nadia Natasha, Ghina Rabbani, Nofrijon Sofyan, Johny Soedarsono, Agus Prasetyo, Ahmad Maksum, Rini Riastuti, and Isnanda Nuriskasari

Private Company Technology Center

Primary resources are typically used in lithium extraction. Unfortunately, it impacts the dependency on the availability of primary resources to fulfill the lithium demand. Therefore, the use of secondary resources can be an alternative to using lithium resources. Gold bullion slag is an example of a potential secondary resource used as a lithium source because it contains 0.009 % lithium. This research aims at increasing lithium recovery from the gold bullion slag by studying the effects of various variables to enhance lithium recovery. Lithium extraction was carried out via HCl leaching process with concentrations of 0.5, 1.0, 1.5, and 2.0 M at 25, 40, 55, and 70 °C for 15, 30, 60, and 120 minutes. Inductively coupled plasma-optical emission spectrometry (ICP-OES) was used to examine lithium level, whereas scanning electron microscope equipped with energy dispersive X-ray spectroscopy (SEM-EDX) was used to look over the morphology. The significance of the recovery value was analyzed statistically using analysis of variance (ANOVA). The optimum variables to reach 98 % as the highest lithium recovery percentage are 1 M HCl at 55 °C for 60 minutes. ANOVA results on the acid concentration significance of the recovery value show that the p-value (0.001) is smaller than the alpha value (0.005). While, ANOVA results on the temperature and time significance of the recovery value show that the p-value (0.894) is greater than the alpha value (0.005) and p-value (0.9986) is greater than the alpha value (0.005), respectively. Analysis showed that variation in HCl concentration affected the lithium recovery value; however, temperature and time of leaching had an insignificant effect on lithium recovery. These data show that slag can be used as alternative resources to produce the lithium

Agus Paul Setiawan Kaban, Johny Wahyuadi Soedarsono, Wahyu Mayangsari, Mochammad Syaiful Anwar, Ahmad Maksum, Aga Ridhova, and Rini Riastuti

MDPI AG

This work reports the anti-corrosion behavior of liquid smoke from rice husk ash to unveil the contribution of its active compounds in 1 M HCl solution. In this study, the developed methodology to test, analyze, and model the novel type of green corrosion inhibitor for C1018 was characterized using Electrochemical impedance spectroscopy (EIS), Potentiodynamic polarization, and deep learning methods. The inhibitor structure was characterized by Fourier transform infrared analysis (FTIR) and Ultraviolet–visible spectroscopy (UV-Vis). The surface characterization of mild steel immersed in blank and 80 ppm solution inhibitor was performed using Atomic force microscopy (AFM) analysis. The corrosion test results show that the inhibitor is considered a mixed-type inhibitor to achieve the optimum inhibition of 80 ppm at 323 K, reaching up to 99% inhibition efficiency. The AFM results show a smoother surface given a lower skewness parameter at −0.5190 nm on the treated mild steel. The artificial neural network demonstrates the lower overfitting on the inhibited steel, a higher accuracy prediction of 81.08%, and a lower loss rate of 0.6001 to model the relationship between the EIS and Potentiodynamic polarization and the evolution of the passive layer on the treated mild steel. The experiment agrees well with the prediction result to model the adsorbed inhibitor. The work can be used as a guideline to pave the way for subsequent applicability in developing green corrosion inhibitors based on experimental and artificial intelligence approaches.

Nurhayati Indah Ciptasari, Murni Handayani, Caesart Leonardo Kaharudin, Afif Akmal Afkauni, Adhi Dwi Hatmanto, Isa Anshori, Ahmad Maksum, Rini Riastuti, and Johny Wahyuadi Soedarsono

Private Company Technology Center

Heavy metals are pollutants that are harmful to living things and the environment can be degraded by microbes or understood by other living things so that they can cause health problems. One of the heavy metals that is often found in wastewater is lead. Lead is widely used in the manufacture of batteries, metal products such as ammunition, cable coatings, Polyvinyl Chloride (PVC) tubing, solder, chemicals and dyes This use causes humans to be exposed to large amounts of lead. One method to deal with lead pollution is to use photocatalysts. Photocatalysts react with heavy metals and reduce them so that the level of toxicity becomes lower than before through photocatalytic reactions. In this study, synthesis of reduced graphene oxide/silver nanoparticle nanoparticles was performed by facile hydrothermal methods for photocatalytic degradation of Pb ion. The characterization results indicate that the synthesis has been successfully carried out. The successful result of rGO/AgNPs nanocomposites synthesis was proved by several techniques such as X-ray diffraction analysis, Raman, UV-Vis spectroscopy, Scanning Electron Microscopy (SEM) and Energy Dispersive X-Ray analysis (EDX). This indicates the presence of these groups in the graphene oxide and rGO/AgNPs samples, respectively. The resulting rGO/AgNPs nanocomposite has an absorbance peak at a wavelength of 267 nm. The diffraction peaks for nanocomposites rGO/AgNPs and their Miller indices were 38.08° (111), 44.16° (200), 64.44° (220), and 77.44° (311). The Raman spectra of rGO/AgNPs exhibits D bands at 1334,13 with intensity of 630,60 cm−1 and G band at 1594,61 with intensity of 477,29 cm−1. The ID/IG ratio rGO/AgNPs-NaBH4 is ~1,32. Furthermore, the photocatalytic activity test results showed that the rGO/AgNPs nanocomposite was able to reduce Pb2+ to Pb with a maximum exposure time of 1.5 hours

Rini Riastuti, Giannisa Mashanafie, Vika Rizkia, Ahmad Maksum, Siska Prifiharni, Agus Kaban, Gadang Priyotomo, and Johny Soedarsono

Private Company Technology Center

Corrosion in API 5L steel under 1M HCl is a common issue; hence, creating a more effective and naturally-based inhibitor is critical. In this research, Syzygium Cumini leaf extract (SCLE) was used as a new green corrosion inhibitor under acidic conditions. The inhibition properties of the novel cumini extract were thoroughly characterized using potentiodynamic polarization (PDP), electrochemical impedance spectroscopy (EIS), Fourier-transform infrared spectroscopy (FTIR), and atomic force microscope (AFM). The results show that the cumini inhibitor has excellent corrosion inhibition with 93 % inhibition efficiency. The adsorption behavior of the inhibitor follows the Langmuir Adsorption Isotherm due to the nearness of R2 to unity. The potentiodynamic and electrochemical measurements demonstrate the mixed type of corrosion inhibitor. Thermodynamic calculation of ΔGads is – 18.41 kJ mol-1 showing the physical adsorption process between the inhibitor and metals. Further inspection of ΔHads at ‒58.93 kJ mol-1 considers releasing energy during adsorption. The FTIR results agree with the increased growth of passive layers due to the adsorption of polyphenol and flavonoids on metals. Remarkably, the adsorption peak at 3266.59 cm-1 corresponds to the adsorption of –OH. The peak at 1612.56 and 1698.4 cm-1 is attributed to C=C and C=O functional groups. The above functional groups serve as adsorption centers to reduce the corrosion effect. The surface treatment of AFM indicated a good relationship with the functional group characterization and confirmed the significant corrosion rate reduction. This work can be used as a benchmark to develop a natural plant as a corrosion inhibitor.

Faiz Irza Ramadhan, Johny Wahyuadi M. Soedarsono, Rini Riastuti, and Ahmad Maksum

IOP Publishing

Abstract One of the methods commonly used to treat biomass waste, including rice husks, is pyrolysis and gasification, both of which produce smoke that can disturb the surrounding environment. This study aims to optimize the conversion process of smoke released in the pyrolysis process of rice husks into two products at once, namely liquid smoke and producer gas. This study designed a Liquid Collection System (LCS) with a shell and tube type knock-down condenser mechanism where the hot smoke is cooled so that the components of the condensed smoke (become liquid smoke) are separated from the non-condensable components (become producer gas). The composition of the LCS coolant, a mixture of Ethylene Glycol and Water, is simulated with the help of Computational Fluid Dynamics (CFD) software to optimize the heat transfer effectiveness value obtained. The simulation results show that the heat transfer efficiency of the volume variation of Ethylene Glycol in the mixture with the volume ratio of Ethylene Glycol and Water is 0:100, 10:90, 20:80, and 30:70 is 9.43%, 13.21%, 15.32%, and 15.43%, respectively. The highest efficiency value was obtained at the highest Ethylene Glycol content, which was a ratio of 30:70.

Mohamad Ramadani Rudiatama, Hamdi Hamdi, Dianta Mustofa Kamal, Johny Wahyuadi M. Soedarsono, and Ahmad Maksum

IOP Publishing

Abstract This study reports the simulation of rice husk pyrolysis units in various sizes of chimneys to investigate the effect of chimney diameter on temperature and heat distribution. The modeling design was carried out using Solidworks 2020 software with 3d modeling, and flow simulation features where the diameters of the chimneys were varied, namely 3, 4, 5, 6, and 8 inches. Simulation of the pyrolysis process with an input temperature of 450 °C and an average fluid velocity of 2.344 m/s for chimney diameters of 3, 4, 5, 6, and 8 inches has resulted in a condenser heat-temperature (TH) of 169.84 °C, 170.04 °C, 171.36 °C, 170.31 °C, and 168.05°C. It produces cold-temperature (TC) of 41.97 °C, 42.88 °C, 42.31 °C, 42.38 °C, and 45.35°C, respectively. The simulation results also show that the larger the chimney size of the pyrolysis tank, the greater the need for heat from the stove fire; conversely, the tank capacity of the husk becomes smaller.

Agus Kaban, Wahyu Mayangsari, Mochammad Anwar, Ahmad Maksum, Taufik Aditiyawarman, Johny Soedarsono, Aga Ridhova, and Rini Riastuti

Private Company Technology Center

The work provides the more comprehensive development of Liquid Smoke from Rice Husks Ash (RHA). Notably, the study focuses on the interaction between the primary molecules of inhibitor and mild steel, including thermodynamic calculation and surface treatment upon addition of inhibitor. The electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization (PP) characterization were utilized to evaluate the anticorrosion of RHA. The Raman Spectroscopy pre and post-addition of RHA’s inhibitor were used to compare the adsorbed functional group of inhibitors. Moreover, the thermodynamic calculation of the inhibitor’s adsorption determines the types of adsorption of the inhibitor. As a result of the adsorption process, the Scanning Electronic Microscope-Energy Dispersive X-Ray (SEM-EDX) aided by The Atomic Force Microscopy (AFM) and Contact Angle Test was implemented to unveil the surface treatment and the change of elemental composition after the addition of an 80 ppm inhibitor. The PP and EIS results show a significant depression of the current density at ‒2.75 μA·cm2 in 80 ppm solution with the highest inhibition efficiency of 99.82 %. The superior inhibition correlates to the adsorption of Si–OH, C–C, C–O–C, >C=O, complex structure, and –OH at wavenumber 458, 662, 1095, 1780, and 3530 cm-1. The LS shows a significant surface area of protection of 0.9982 and high adsorption constant (Kads) at 11.648. The calculated ΔGads of ‒6.59 kJ/mol unveils the chemisorption in nature. At the same time, a combination of 20 and 80 ppm solution is predicted adsorbed horizontally to reduce the contact between the solution and substrate, as shown in SEM and AFM results. It also increases the contact angle and their corresponding hydrophobicity

Agus Paul Setiawan Kaban, Wahyu Mayangsari, Mochammad Syaiful Anwar, Ahmad Maksum, Rini Riastuti, Taufik Aditiyawarman, and Johny Wahyuadi Soedarsono

Elsevier BV

A.B. Prasetyo, A. Khaerul, W. Mayangsari, E. Febriana, A. Maksum, J. Andinie, F. Firdiyono, and J.W. Soedarsono

National Library of Serbia

A research using ferronickel slag, the by-product of ferronickel production, as raw material for magnesium extraction was carried out. It is essential to upgrade the value of ferronickel slag instead of used directly for reclamation materials. Moreover, the accumulation due to increasing ferronickel demand as well as the environmental contamination due to various potentially toxic elements contained in the ferronickel slag could be prevented. The general objective of this study is to utilize the ferronickel slag for magnesium materials. The specific objective is to determine the optimum conditions of magnesium extraction in the process of alkali fusion followed by hydrochloric acid leaching. A novel method for magnesium extraction from ferronickel slag was carried out through reducing silica content followed by acid leaching method. Alkali fusion of the mixture of ferronickel slag and Na2CO3 at 1000?C for 60 minutes, followed by water leaching at 100?C for 60 minutes with solid to liquid percentage of 20 % was carried out to separate the silica. The leaching residue resulted from water leaching was then leached using hydrochloric acid solution to extract magnesium. The leaching temperature and time as well as the hycrochloric acid concentration were varied in the acid leaching process. Alkali fusion process proved the sodium silicate can be generated and that it can be separated in the water leaching to the leached solution. Meanwhile, the leaching residue was leached using hydrochloric acid to extract the magnesium. The highest magnesium extraction percentage is 82.67% that resulted from an optimum acid leaching condition with temperature of 80?C for 30 minutes using 2M HCl solution. Based on the kinetics study, the activation energy (Ea) for the leaching reaction of magnesium at atmospheric pressure between 32?C to 80?C is 9.44 kJ/mol and affected by diffusion and chemical reactions.

Agus Paul Setiawan Kaban, Aga Ridhova, Gadang Priyotomo, Berna Elya, Ahmad Maksum, Yunita Sadeli, Sutopo Sutopo, Taufik Aditiyawarman, Rini Riastuti, and Johny Wahyuadi Soedarsono

Private Company Technology Center

This work covers the effectiveness of the White tea extract as a green corrosion inhibitor and is correlated to the strength and stability bonding between the phenolic molecule and the Fe atoms in mild steel and how this interaction can be studied by altering the concentration and temperature. White tea has received considerable attention due to its capability as a corrosion inhibitor and has been extensively studied using electrochemical techniques. However, accurate and systematic functional group identification and surface modification have been missing. Our study sought to demonstrate the quantitative measurement of electrochemical impedance spectroscopy (EIS) complemented by the FTIR (Fourier transform infrared spectroscopy), Total Phenolic Test, and Raman Spectroscopy. The SEM (Scanning Electronic Microscope)/EDX (Energy-Dispersive X-Ray Spectroscopy), and AFM (Atomic Force Microscope) were used to study the surface modification. The EIS results show that the optimum inhibition efficiency was 96 % in a solution of 80 ppm at 60 °C. Acetone 70 % was used to extract White tea and gives 14.17±0.25 % phenolic compound. Spectroscopic studies show -OH, Aromatic C=C, C=O and C-O-C become major contributors in the adsorption process and are found on the surface of metals as corrosion protection. Meanwhile, the thermodynamic calculation shows the White tea was adsorbed chemically. The nearness of R2 to 1 shows the adsorption agrees with the Langmuir adsorption isotherm. Eventually, the surface modification revealed that phenol molecules are responsible to reduce the corrosion rate at 16.38×10-3 mpy. Our results are expected to provide a guideline for future research in White tea as a green corrosion inhibitor

Wahyu Mayangsari, Isma Nur Avifah, Agus Budi Prasetyo, Eni Febriana, Ahmad Maksum, Reza Miftahul Ulum, Florentinus Firdiyono, Rudi Subagja, and Johny Wahyuadi Soedarsono

Private Company Technology Center

Ferronickel slag is a by-product of the nickel smelting process. Recycling of ferronickel slag is required since it contains valuable elements besides its potency to pollute the environment. In order to take advantage of the valuable materials and reducing the potential hazard, beneficiation of ferronickel slag is essential. Alkali fusion of ferronickel slag using Na2CO3 in the roasting process was carried out. This study aims to determine the decomposition of the mixture of ferronickel slag-Na2CO3 in the roasting process. Roasting temperature and time were 800–1,000 °C and 60‒240 minutes, respectively. Characterizations of the ferronickel slag were conducted by XRF, ICP-OES, XRD and SEM-EDS. Meanwhile, roasted products were characterized using ICP-OES, XRD and SEM-EDS. Characterization of the ferronickel slag indicates that Mg and Si are the main elements followed by Fe, Al and Cr. Moreover, olivine is detected as the main phase. The roasting process caused percent weight loss of the roasted products, which indicates decomposition occurred and affected the elements content, phases and morphology. The roasting process at about 900 °C for 60 minutes is a preferable decomposition base on the process conditions applied and the change of elements content. Aluminum (Al) and chromium (Cr) content in the roasted products upgraded significantly compared to iron (Fe) and magnesium (Mg) content. Olivine phase transforms to some phases, which were bounded with the sodium compound such as Na2MgSiO4, Na4SiO4 and Na2CrO4. The rough layer is observed on the surface of the roasted product as a result of the decomposition process. It indicates that liquid-solid mass transfer is initiated from the surface

Naufal Wirasyawal Luneto, Bagas Muhammad Syafa, Ahmad Maksum, Agus Budi Prasetyo, Reza Miftahul Ulum, and Johny Wahyuadi Soedarsono

AIP Publishing

Muhammad Darryl Alfariz, Wahyu Mayangsari, Agus Budi Prasetyo, Ahmad Maksum, Totok Prasetyo, Reza Miftahul Ulum, and Johny Wahyuadi Soedarsono

AIP Publishing

Arryan Jibril R., Prinanda Doni Santoso, Agus Budi Prasetyo, Ahmad Maksum, Reza Miftahul Ulum, and Johny Wahyuadi Soedarsono

AIP Publishing

Samantha Aziza Nurarani, Shalsabila Nandya Miryana Usman, Agus Budi Prasetyo, Ahmad Maksum, Totok Prasetyo, Reza Miftahul Ulum, and Johny Wahyuadi Soedarsono

AIP Publishing

Shalsabila Nandya Miryana Usman, Samantha Aziza Nurarani, Agus Budi Prasetyo, Ahmad Maksum, Totok Prasetyo, Reza Miftahul Ulum, and Johny Wahyuadi Soedarsono

AIP Publishing

Bagas Muhammad Syafa, Naufal Wirasyawal Luneto, Ahmad Maksum, Agus Budi Prasetyo, Reza Miftahul Ulum, and Johny Wahyuadi Soedarsono

AIP Publishing

Dimas Nugroho, Ahmad Maksum, Delfiendra, and Johny Wahyuadi Soedarsono

AIP Publishing