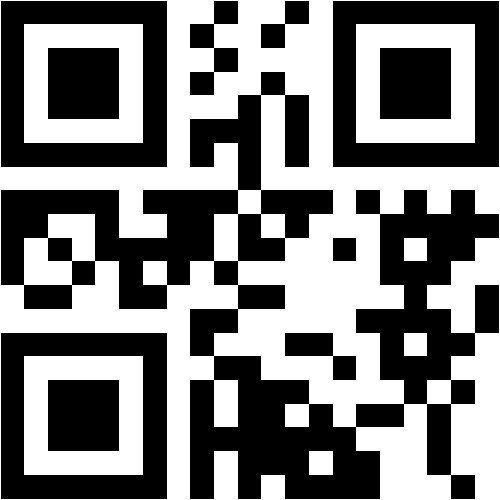

Raja Balakrishnan

@iiitdm.ac.in

IIITDM Kancheepuram

Scopus Publications

Scholar Citations

Scholar h-index

Scholar i10-index

Scopus Publications

R. Chandrasekaran, M. Satish Kumar Reddy, K. Selvajyothi, and B. Raja

Wiley

Rinku Kumar Gouda, G Srinivasan, V Umesh, and B Raja

Springer Science and Business Media LLC

T. Jeyapradhap, G. Srinivasan, and B. Raja

Elsevier BV

Rajasekar Krishnamoorthy and Raja Balakrishnan

Informa UK Limited

G. Srinivasan, M. Muneeshwaran, Chi-Chuan Wang, and B. Raja

Springer Science and Business Media LLC

An experimental study was carried out to analyze the cooling curve and drying behavior of static and spin-frozen samples (distilled water and skimmed milk) in liquid immersion freeze–drying process. The freezing process was carried out in two modes: static freezing and spin freezing. Subsequently, the immersion drying process of static and spin-frozen samples was performed in a static condition. The liquid immersion method aids in heating the entire surface area of the shell containing the frozen sample, which subsequently improves the heat transfer rate and reduces the drying time. The comparison of the cooling curve of the static and spin freezing processes showed that the supercooling phenomenon has not occurred in the spin freezing process against the static one. A detailed analysis of the drying rate, drying time, moisture content retention, heat transfer coefficient, and heat load during the drying process of static and spin-frozen samples is presented in this study. The results showed that the spin-frozen sample exhibited a larger ice-vapor surface area, lower ice thickness, higher drying rate, lesser drying time, and higher heat transfer coefficient than the static-frozen sample. The product thickness attained via spin freezing is about 88% smaller than the static one. Consequently, the drying time of the spin-frozen sample is almost reduced by 80% as compared to the static case.

R. Chandrasekaran, M. Sathishkumar Reddy, B. Raja, and K. Selvajyothi

Wiley

K Rajasekar and B Raja

Springer Science and Business Media LLC

M. Muneeshwaran, G. Srinivasan, B. Raja, and Chi-Chuan Wang

Springer Science and Business Media LLC

The vial design feature, such as the base curvature, acts as the primary heat transfer barrier in the lyophilization process. In this study, heat and mass transport characteristics of mannitol (5%) during vial freeze-drying are numerically investigated by including the vial base curvature effects. The influence of the product fill height, chamber pressure, and the vial base curvature on the product temperature, drying time, and mass transfer resistance is analyzed in detail. The diameter of the vial is taken as 15 mm, while the fill height of the product is varied from 3 to 5 mm. The chamber pressure is maintained between 5 and 50 Pa. The results revealed that the product with a 3 mm fill height experienced a 2.5 °C lower temperature than the product with a 5 mm fill height. As opposed to the flat vial predictions, if the vial base curvature effects are considered, the drying time is increased by 1.96 and 3.8 h for the 3 mm and 5 mm fill heights, respectively. The increased drying time is attributed to the reduced direct contact area between the vial and shelf and the vapor entrainment in the gap. The results showed that the dry layer mass transfer resistance contributes to 95% of the total mass transfer resistance; however, the contribution of semi-stoppered vial resistance is 1–2% only.

K. Rajasekar and B. Raja

Pleiades Publishing Ltd

R. Chandrasekaran, A. Srivani, B. Raja, and K. Selvajyothi

IEEE

Development of Electric Vehicles (EV) in recent year’s lithium batteries becomes as the principal energy source due to the peak value of energy density, better power density and, long lifespan. Fast and proficient charging of batteries is a must for battery propelled automobiles. However, it takes a few minutes to fuel the petrol-powered vehicles but an EV takes 4-6 hours to complete the charging depends on C-rate. This paper presents the modeling and simulation of a multi current charging method for a two-wheeled electric vehicle. The proposed method uses a closed-loop control to derive the charging current through a buck converter power conditioning circuit. To validate the proposed charging method, the circuit is simulated in MATLAB/ Simulink environment and the results are compared with that of the constant current charging (CC) method and Constant Current-Constant Voltage (CC-CV) charging method.

G Srinivasan and B Raja

Springer Science and Business Media LLC

An experimental study on heat transfer characteristics of shelf heat exchangers, which are used in small-scale freeze dryers, is presented in this paper. The proposed heat exchanger consists of the multiport mini-channel flow paths, and a comparison with a conventional serpentine is carried out based on uniformity of the product temperature achieved. The experimental results indicate that the mini-channel shelf has better temperature uniformity than the latter. Skimmed milk is used as the test fluid. In the freezing and drying process, the product temperature variation is minimal in the mini-channel heat exchanger, with a variation of 12.5 % and 25%, respectively, and the heat transfer coefficient is found to be from 140 to 267 Wm −2 K −1 . The moisture content in the product reduces to 50 % in 2 hours, and the drying rate is higher at 0.032 kg hr −1 after 1 hour of the drying process. The redesign of the heat exchanger will be an essential tool to improve the performance with uniform temperature distribution on the product and to improve the product quality.

M. Satish Kumar, Thumpiri Reddy Manasa, B. Raja, and K. Selvajyothi

IEEE

In this paper, the 2RC electrical equivalent circuit of the Li-ion battery (LIB) is considered for deducing a state space model. The estimation of State of Charge (SoC) and terminal voltage of the battery is derived through Coulomb counting and Extended Kalman filter for constant current discharge under a Urban Dynamometer Driving Schedule (UDDS) cycle. The parameters required for the state space model are determined experimentally for different discharge currents of a single cell. The design of battery pack for different power requirements like two, three and four-wheeler electric vehicles (EVs) from these 18650 cells is deduced and the performance indices are estimated based on an UDDS cycle. The estimated SoC and terminal voltage are compared with those obtained through preliminary Coulomb counting and 2RC model.

Ganeshmurthy Srinivasan and Balakrishnan Raja

Wiley

Spin freeze‐drying process is a recently proposed method to achieve continuous processing of unit doses in freeze‐drying application. An experimental study is carried out to investigate the heat transfer and drying characteristics of a spin‐frozen liquid product. To enhance heat transfer, unlike freeze drying performed in shelves, the shell is immersed into a temperature‐controlled bath. The influence of different ramping condition of bath temperature on drying rate, time and variation of moisture content in spin‐frozen products (deionized water and skimmed milk) are analyzed and reported in this paper. Among different ramping conditions, ramping of bath temperature to 10°C resulted in higher drying rate (1.8 kg hr⁻¹ m⁻²) and lesser drying time (44%). The overall heat transfer coefficient (Kᵥ) between the bath and product is evaluated for the above condition in both the test liquids. This direct contact type heat transfer helps in reducing air gap resistance and radiation effect, which primarily helps in minimizing thermal resistances. The effect of dry layer resistance is minimal in the spin‐frozen product due to lower product thickness and larger ice‐vapor surface area. PRACTICAL APPLICATIONS: The spin‐frozen sample is dried either by using an infrared (IR) heater or by placing on a shelf. Limitations using IR heater include positioning of the vials (the distance between the vials and IR source) and selecting suitable IR window material and thickness. In the case of the shelf, conduction resistance between shelf and vial, radiation resistance inside the chamber and air gap resistance present between vial and shelf plays a major role. The thermal resistance is minimal in the immersion method due to the absence of air gap resistance and radiation effect. Hence, an alternative approach is discussed using immersion drying method to achieve continuous vial processing and uniformity among vials. Hence, freeze‐drying process can also be shifted to continuous production mode like prefilling and packaging.

G. Srinivasan and B. Raja

Springer Science and Business Media LLC

An experimental study on formation of ice patterns during spin freezing of liquid in vials and the effect of such ice patterns in the freeze-drying process is investigated. The process is carried out in vials for liquids such as distilled water and skimmed milk which are immersed and spun in a temperature control bath maintained at −25 °C. The occurrence of different ice patterns are demonstrated using two vials with l/d ratio of 2.4 (V1) and 3.9 (V2) with the liquid fill volume varied between 20% and 85%. It is observed that depending on the l/d ratio, speed of rotation and fill volume, different ice patterns such as spiral, cone shape and uniform annular patterns occur. Also, the subsequent drying process effectively depends on the type of ice pattern that resulted in the freezing process. Among the different ice patterns, the uniform annular pattern exhibited a better drying rate.

G. Srinivasan, M. Muneeshwaran, and B. Raja

Springer Science and Business Media LLC

The transient heat and mass transfer characteristics of the freeze-drying process of milk in a vial is numerically investigated. The paper reports the influence of semi- stoppered vial on mass transfer resistance and the relative importance of the bottom curvature of the vial on the drying time. Moreover, the variation of product temperature and mass transfer resistance as a function of time is predicted. The study revealed that the vial heat transfer coefficient strongly depends on chamber pressure; however, the effect of shelf temperature is minimal. The analysis is conducted for two fill heights (8.25 and 16.5 mm.) It is observed that the presence of curvature at the bottom of the vial increases the primary drying time but decreases the product temperature. Based on the simulation, it is observed that 16.5 mm product fill height provided higher mass transfer resistance than 8.25 mm fill height.

V. Umesh, S. Balavignesh, and B. Raja

Pleiades Publishing Ltd

A tailor-made convective heat transfer test facility is constructed to study the single-phase convective heat transfer of deionized water and 30 vol% and 60 vol% aqua–ethylene glycol in a stainless steel tube of 4 mm in inner diameter and 1 m in length. The heat flux is varied between 1 and 4 kW·m−2 and for mass flux ranging from 160 to 475 kg·m−2 s−1. The experiments were predominantly conducted only for laminar flow regime. Finally, the heat transfer coefficient is recorded and compared with the conventional theories. It is observed that the presence of ethylene glycol in water decreases the heat transfer coefficient by more than 50%, due to the decreased Reynolds number and thermal conductivity of the mixture.

V. Umesh, S. Bala Vignesh, and B. Raja

Informa UK Limited

This article presents the nucleate boiling heat transfer characteristics of acetone at one bar on smooth and enhanced circular stainless steel surfaces (SS 316) of 20 mm diameter for heat flux between 1 and 4 W cm− 2, which mimic the operating condition of a typical immersion electronic cooling system. The experimental heat transfer coefficient from the smooth surface is validated against Borishanski correlation [1] within acceptable limits of ± 5%. The steel smooth surface is enhanced by providing 100 equally spaced indents of 0.5 mm diameter and 0.05 mm depth. The experimental results indicate that the enhanced surface shows a good shift in the boiling curve and thus, enhancing the nucleate boiling heat transfer at a lesser wall super heat when compared to the smooth surface by around 35% for tested condition. The effect of subcooling on nucleate boiling in enhanced surface reveal that the heat transfer coefficient degrade by 40 to 55% for a sub cooling of 5 to 10 K. The influence of material is studied by a similar enhanced surface made of brass and compared for the same working condition. The brass enhanced surface showed an improved of around 50% against the steel-enhanced surface. Also, the influence of fluid is studied by comparing acetone and n-pentane, which showed that the latter an enhancement in heat transfer coefficient of 50% over the former.

P. Balachander and B. Raja

Springer Science and Business Media LLC

Abstract

An experimental investigation on the flow boiling heat transfer characteristics of R404A and R134a for low mass flux and heat flux conditions in a smooth horizontal tube is reported. Refrigerant saturation temperatures −15, −10, −5 and 0 °C were considered for the flow boiling conditions. The influence of the mass flux, heat flux and saturation temperature on the heat transfer coefficients of R404A and R134a are discussed in detail. The predominant flow pattern for the tested conditions is confirmed to be the stratified-wavy flow. The study revealed that the heat transfer coefficient is a strong function of the heat flux, throughout the flow boiling process, and the nucleate boiling contribution is much higher for R404A compared to that of R134a. The heat transfer characteristic of R404A is compared with that of R134a, to understand their relative performance in low temperature appliances. A modified correlation for the flow boiling heat transfer coefficient of R404A is developed to fit the experimental results of R404A.

V. Umesh and B. Raja

Elsevier BV

Abstract Nucleate boiling heat transfer characteristic of pentane and CuO-pentane nanofluid is studied on smooth and enhanced circular brass surfaces of 20 mm diameter. The study is carried out at a pressure of 1 bar for the heat flux ranging between 1 and 10 W cm −2 . The measured experimental heat transfer coefficient of pure pentane on the smooth brass surface is validated against established correlation within acceptable limits of ±5%. Further, two enhanced surfaces are prepared from plain surfaces by grooving in two perpendicular directions with pitches of 1 and 1.5 mm surfaces, which are named as fine and coarse surfaces respectively. Also, the effect of surface material on boiling is studied on similar enhanced surfaces made of steel, where the brass surfaces showed a 20–30% higher heat transfer coefficient for the tested condition. Further, the presence of nano-particle in the base fluid influence the heat transfer coefficient and the enhancement due to its presence is seen to be higher for lower volume fraction nanofluid.

R. Karthik, R. Harish Nagarajan, K. S. Praveen, and B. Raja

Pleiades Publishing Ltd

The thermal conductivity enhancement of CuO-deionized water nanofluids over the deionized water is measured using a tailor-made measurement device that uses the 3-ω technique. The measurement and prediction are carried out for temperatures between 15 and 35°C and volume fractions of 0.025%, 0.05%, and 0.1%. The enhancement in thermal conductivity over the base fluid for the tested conditions is observed to be 13 to 25%. A comparison between the measured data and the predicted ones using established correlations reveals that the deviation in prediction is within ±10%.

L. Godson, K. Deepak, C. Enoch, B. Jefferson, and B. Raja

Springer Science and Business Media LLC

Abstract An experimental study is carried out to investigate the heat transfer characteristics of silver/water nanofluids in a shell and tube heat exchanger. The test matrix is worked out in the turbulent regime with Reynolds number varying between 5000 and 25,000, particle volume concentrations of 0.01%, 0.03% and 0.04% and for heat flux varied between 800 W/m 2 and 1000 W/m 2 , which is sourced from a solar flat plate collector. The influence of mass flow rate, inlet temperature and volume concentration on the LMTD, effectiveness, convective heat transfer coefficient and pressure drop are studied. The results showed an increase in convective heat transfer coefficient and effectiveness of silver/water nanofluids as the particle volume concentration is increased. A maximum enhancement in convective heat transfer coefficient of 12.4% and effectiveness of 6.14% is recorded. It is also observed that the apparent increase in the heat transfer coefficient is due to the enhanced thermo-physical properties of the nanofluids, and delayed development of boundary layer in the entrance regions due to the addition of nanoparticles.

S. Balavignesh, V. Umesh, and B. Raja

Elsevier BV

Abstract The experimental study on the flow boiling heat transfer of n-pentane conducted in a mini channel of 1.6 mm inner diameter is presented in this paper. The heat transfer coefficient is measured for mass flux in the range from 250 to 750 kg m-2 s-1 in steps of 250 kg m-2s-1 and the heat flux is varied using an electrical heater arrangement from 1.6 to 3.2 W cm-2 (16 to 32 kW m-2). The flow pattern is ensured using established flow pattern maps and confirmed to be predominantly annular flow for all test conditions. The heat transfer coefficient is profoundly influenced by both heat flux and mass flux at higher vapour quality. The experimental heat transfer coefficient is seen to vary between 650 and 1900 W m-2 K-1. The measured pressure drop varies between 0.12 bar and 0.35 bar for the tested condition.

Siddharth Komini Babu, K.S. Praveen, B. Raja, and P. Damodharan

Elsevier BV

Abstract A modified measurement device to measure thermal conductivity of fluids using transient hot-wire technique has been designed, developed, tested and presented in this paper. The equipment is designed such that the thermal conductivity could be measured using both single wire sensor of different length and dual wire sensor. The sensor, which is also a heater, is a platinum micro-wire of 50 μm diameter. The influence of wire length on the measurement of thermal conductivity of fluids is tested using two single wires of length 50 mm and 100 mm. The thermal conductivity is also measured using a dual hot wire arrangement; which is achieved by placing the 100 mm and 50 mm wires in a Wheatstone bridge with the 100 mm wire as the sensor and 50 mm wire as a compensation wire. The apparatus requires a 100 ml of test fluid to perform the experiment. The testing temperature of the test fluid during the experimentation can be suitably varied by the choice of heat exchange fluid used in the apparatus. Water is chosen as testing fluids for primary standards. When compared to single wires, the thermal conductivity of the fluids measured is consistent with dual-wire method with an uncertainty of ±0.25%.

Lazarus Godson, B. Raja, D. Mohan Lal, and S. Wongwises

ASME International

The convective heat transfer coefficient and pressure drop of silver-water nanofluids is measured in a counter flow heat exchanger from laminar to turbulent flow regime. The experimental results show that the convective heat transfer coefficient of the nanofluids increases by up to 69% at a concentration of 0.9 vol. % compared with that of pure water. Furthermore, the experimental results show that the convective heat transfer coefficient enhancement exceeds the thermal conductivity enhancement. It is observed that the measured heat transfer coefficient is higher than that of the predicted ones using Gnielinski equation by at least 40%. The use of the silver nanofluid has a little penalty in pressure drop up to 55% increase 0.9% volume concentration of silver nanoparticles.